What is Inventory Control

Inventory control is the process of overseeing and managing the stock of goods a business possesses. It involves all aspects of inventory, from purchasing raw materials to storing finished goods. This comprehensive approach ensures a balance between supply and demand, preventing overstocking (which ties up capital) and understocking (which leads to lost sales and unhappy customers). The goal of inventory control is to maintain optimal stock levels, minimize costs, and maximize efficiency throughout the supply chain. Effective inventory control is vital for businesses of all sizes and across all industries. Without proper control, a company can suffer from significant financial losses due to waste, spoilage, theft, or simply being unable to meet customer demand.

Benefits of Effective Inventory Control

Implementing a robust inventory control system provides numerous benefits for a business. One of the primary advantages is reduced costs. By minimizing waste, preventing obsolescence, and optimizing storage space, companies can significantly lower their operational expenses. Efficient inventory control also improves cash flow. Accurate tracking and forecasting allow businesses to purchase only what they need, freeing up capital for other investments. Moreover, effective inventory control enhances customer satisfaction by ensuring products are available when needed. This leads to fewer stockouts, quicker order fulfillment, and ultimately, happier customers. Finally, it provides valuable data for better decision-making, allowing for more informed purchasing, production, and sales strategies. These benefits collectively contribute to increased profitability and a more competitive position in the market.

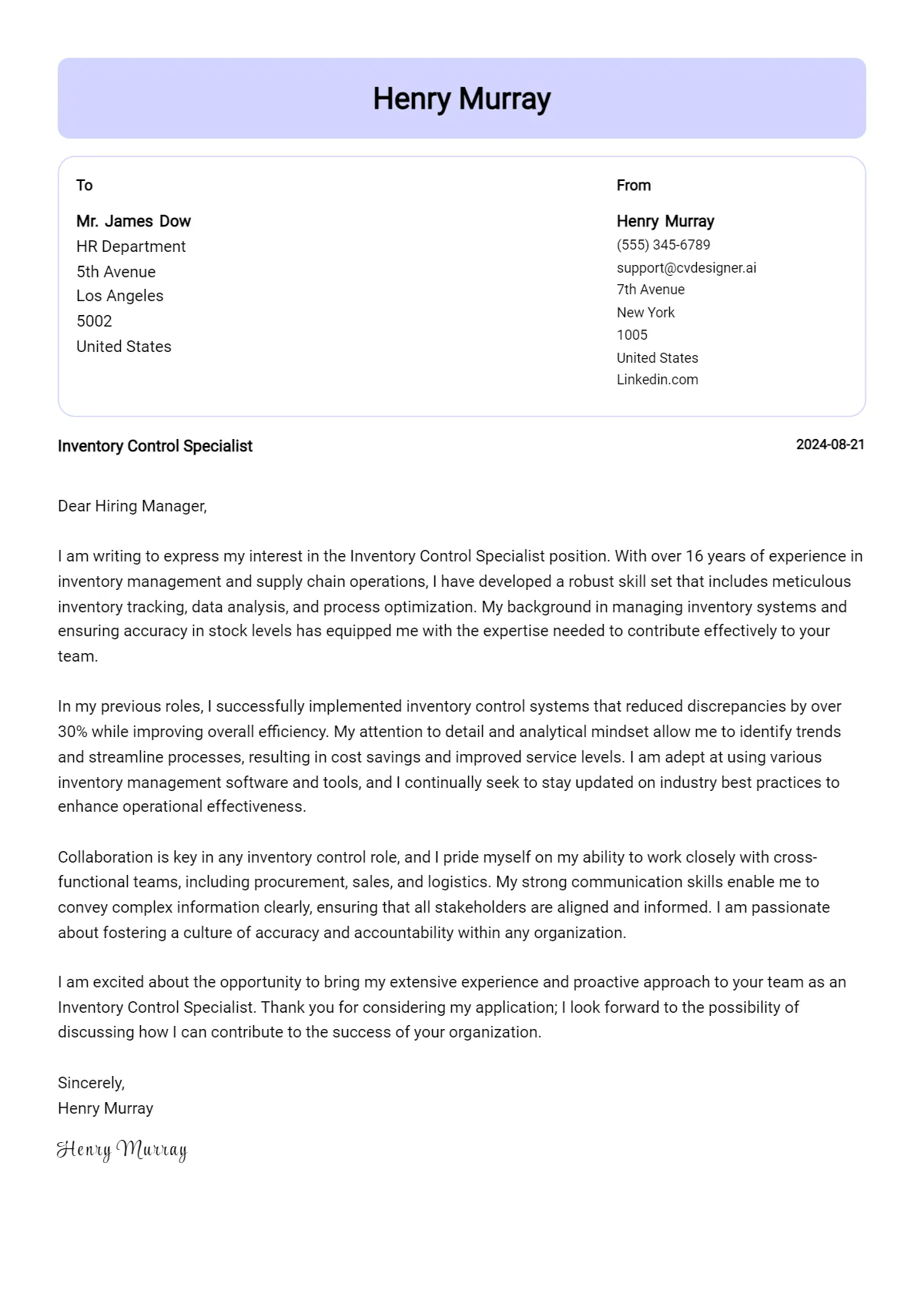

How to Write a Great Inventory Control Cover Letter

A well-crafted cover letter is essential when applying for an inventory control position. It’s your first opportunity to make a strong impression and demonstrate your suitability for the role. The cover letter should showcase your relevant skills, experience, and achievements in a concise and compelling manner. Tailor your letter to the specific job description, highlighting the qualifications and requirements the employer is seeking. Always address the letter to the hiring manager by name if possible. Demonstrate your understanding of the company’s needs and explain how you can contribute to their success. The letter should complement your resume and provide a more detailed narrative about your career and why you are the ideal candidate.

Highlighting Relevant Skills and Experience

When writing your inventory control cover letter, focus on the skills and experience that directly align with the job requirements. Mention any experience you have with inventory management software, such as SAP, Oracle, or Fishbowl. Detail your proficiency in conducting inventory audits, cycle counts, and reconciliation. Highlight your experience in forecasting demand, managing warehouse operations, and optimizing storage space. Emphasize your ability to analyze data, identify trends, and implement process improvements. Include experience with creating and maintaining inventory reports, managing stock levels, and working with suppliers. Don’t just list skills, provide concrete examples of how you’ve applied them to achieve positive results in previous roles, such as reducing inventory costs or improving accuracy.

Quantifying Achievements for Inventory Control

Use quantifiable data to demonstrate your achievements in inventory control. Instead of simply stating you ‘improved inventory accuracy,’ specify by how much (e.g., ‘Improved inventory accuracy by 15%’). Show the tangible results you’ve delivered in previous roles. For example, ‘Reduced inventory costs by $50,000 annually by implementing a new cycle counting system’. Include numbers whenever possible to showcase your accomplishments and provide concrete evidence of your capabilities. Examples include ‘Managed a stock of over 5,000 SKUs,’ ‘Reduced stockouts by 20%,’ or ‘Processed an average of 100 orders daily with 99% accuracy.’ These details make your cover letter more persuasive and demonstrate the value you can bring to the company. Make sure to align these achievements with the specific needs outlined in the job description to show your direct impact.

Tailoring Your Cover Letter to the Job

A generic cover letter is unlikely to impress a hiring manager. Instead, tailor your letter to each job you apply for. Carefully read the job description and identify the key requirements and qualifications. Customize your letter to highlight the skills and experiences that directly address these requirements. Research the company and understand its industry and goals. Personalize the letter to show that you understand their specific needs and how you can contribute to their success. Mention specific projects or initiatives that align with the company’s objectives. Show genuine enthusiasm for the role and the company. This personalized approach demonstrates your interest and attention to detail, making your application stand out from the competition.

Top 7 Secrets for Inventory Control Success

Secret 1 Implement a Robust Inventory System

The foundation of effective inventory control is a solid inventory management system. This may involve implementing specialized software designed to track inventory levels, manage orders, and forecast demand. The system should provide real-time visibility into all aspects of inventory, from raw materials to finished goods. It should integrate seamlessly with other business systems, such as accounting and sales, to ensure data accuracy and streamline operations. Regularly evaluate and update your inventory system to meet evolving business needs and technological advancements. Consider incorporating features like barcode scanning, RFID technology, or automated reordering to improve efficiency and reduce errors. The proper implementation of an effective system sets the groundwork for streamlined operations.

Secret 2 Optimize Storage and Organization

Efficient storage and organization are critical for maximizing warehouse space, minimizing handling costs, and preventing damage or loss. Implement a well-defined layout that allows for easy access to inventory and efficient movement of goods. Use appropriate storage solutions, such as shelving, racks, and bins, to maximize vertical space and organize items by type or frequency of use. Employ a First-In, First-Out (FIFO) or First-Expired, First-Out (FEFO) system to ensure that older items are used or sold before newer ones. Regularly clean and maintain your storage areas to prevent contamination and ensure a safe working environment. Proper organization prevents bottlenecks, reduces picking times, and helps maintain accurate inventory records. Keep items in a logical order to minimize time spent searching for specific products, boosting overall warehouse efficiency.

Secret 3 Conduct Regular Inventory Audits

Regular inventory audits are essential for verifying the accuracy of your inventory records and identifying discrepancies. Conduct cycle counts or full physical inventories at regular intervals to compare your physical count with your system’s records. Investigate and correct any discrepancies immediately. Document the results of your audits and use the data to identify areas for improvement. Implement corrective actions to prevent future errors, such as improving training, adjusting processes, or updating your inventory management software. Use the data to improve the forecasting of demand. Conduct regular audits to catch discrepancies, which may be caused by theft, damage, or inaccurate record-keeping. This will ensure data accuracy, and help to identify areas where improvements are needed.

Secret 4 Forecast Demand Accurately

Accurate demand forecasting is crucial for maintaining optimal inventory levels and avoiding stockouts or overstocking. Use historical sales data, market trends, and seasonal variations to predict future demand. Consider external factors that may impact demand, such as economic conditions, promotional activities, and competitor actions. Utilize forecasting tools and techniques, such as statistical analysis or machine learning, to improve the accuracy of your predictions. Continuously monitor and refine your forecasts based on actual sales data. Collaborate with sales, marketing, and other departments to gather information and gain insights into upcoming demand. Accurate forecasting minimizes waste, lowers holding costs, and ensures customer satisfaction. The use of accurate data and sales analysis is key to avoiding stockouts.

Secret 5 Use Inventory Management Software

Inventory management software automates many inventory control tasks, improves accuracy, and provides real-time visibility into your stock levels. Choose software that meets your specific business needs, considering factors such as company size, industry, and complexity of your inventory. The software should provide features like automated reordering, barcode scanning, and reporting capabilities. Integrate the software with other business systems, such as accounting and sales, for seamless data flow. Regularly train your team on how to use the software effectively. Ensure that data entry is accurate and consistent. Proper inventory management software improves overall efficiency. Automate tasks and streamline processes. Consider the integration with other business operations to enhance functionality.

Secret 6 Train Your Team Effectively

Well-trained employees are essential for successful inventory control. Provide comprehensive training on inventory management procedures, software, and best practices. Ensure that employees understand their roles and responsibilities. Offer ongoing training to keep employees up-to-date with new technologies and processes. Foster a culture of accuracy and attention to detail. Encourage employees to identify and report any discrepancies or errors. Provide clear documentation and standard operating procedures. Regularly assess the effectiveness of your training programs and make adjustments as needed. Train your team to utilize all processes effectively to improve overall efficiency and success.

Secret 7 Analyze and Improve Processes

Continuously analyze your inventory control processes to identify areas for improvement. Track key performance indicators (KPIs), such as inventory turnover, carrying costs, and order accuracy. Regularly review these metrics to assess the effectiveness of your strategies. Use data and feedback from employees to identify bottlenecks, inefficiencies, and areas where errors are common. Implement process improvements, such as streamlining workflows, automating tasks, or adjusting safety stock levels. Regularly evaluate the impact of your changes and make further adjustments as needed. A commitment to continuous improvement ensures that your inventory control processes remain efficient and effective. Use data to improve forecasting and inventory planning.

Conclusion

Mastering inventory control is vital for any organization looking to optimize its operations and maximize its profitability. By implementing these seven secrets – from establishing a robust inventory system to continuously analyzing and improving processes – businesses can achieve greater efficiency, reduce costs, and enhance customer satisfaction. For job seekers, crafting a compelling cover letter that highlights your skills, experience, and achievements is crucial to landing your dream role in inventory control. Remember to tailor your letter to each job and quantify your accomplishments to make a strong impression on potential employers. By understanding and implementing these principles, individuals and businesses alike can unlock the full potential of effective inventory management and drive sustained success.